Fermenters manufactured by Ashkan EQ Company :

• Operating pressure up to 10 bar

• Operating temperature up to 250 C

• Equipped with PLC controller system

| Fermenter | |

| Model | Capacity (in liter ) |

| RF-US | 75 |

| RF-S | 150 |

| RF-M | 300 |

| RF-L | 500 |

| RF-UL | 1000 |

| Other volumes are custom-made | |

The Fermenters usages:

- Production active material, many kinds of drugs and vaccines for some diseases (e.g. cancer, AIDS and hepatitis)

- Production different kinds of serums

- Production some poisons (e.g. diphtheria by suspension incubation in the fermenter)

| Construction | Aspect Ratio 3:1 | ASME Standard | ||||||||||

| Material Of Construction: 316L SS | Vessel access: spring-assisted man way | |||||||||||

| Finish: 20 Ra [internal /external]. optional: electro polished interior | ||||||||||||

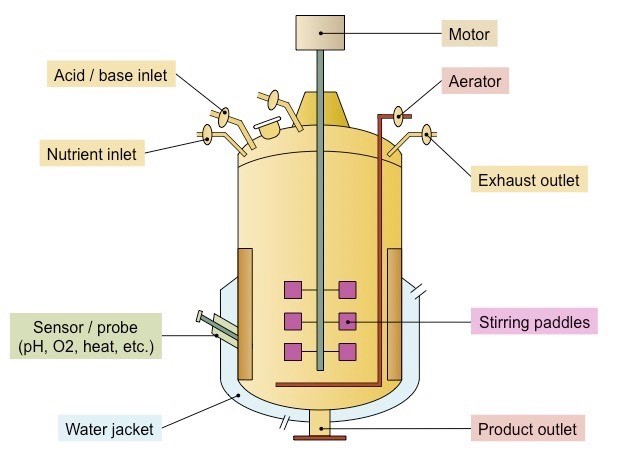

| Agitation | Drive : Bottom or Above Drive , Magnetic or mechanical seal | |||||||||||

| Impeller: Rushton | Baffles: removable,316L stainless-steel | |||||||||||

| Speed(RPM) | 50-500 | 45-450 | 50-400 | 30-300 | 30-350 | |||||||

| AC Motor Size(hp.) | 1 | 5 | 5 | 10 | 20 | |||||||

| Ports | Head plate | 1″ tri-clamp ( DP transmitter/rupture disk/pressure transmitter) | ||||||||||

| 2″ tri-clamp ( spray balls/exhaust condenser/level probes/septum) | ||||||||||||

| Upper side wall | ” NA-Connect (gas overlay) | ” tapered tri-clamps ( SIP/CIP addition valves) | ||||||||||

| 1″ tapered tri-clamp (pressure gauge) | 4″ tapered tri-clamp ( viewing port ) | |||||||||||

| Lower Side Wall | ” NA-connects (RTD/thermoswell) | |||||||||||

| 25mm Ingold ports (pH/spare DO) | ||||||||||||

| 1″ NA-connect (sample valve/sample system/sparge) | ||||||||||||

| Bottom | 1″ Drain valve | Drain flange | 1″ Na-connect Lower DP transmitter | |||||||||

| Piping | Material Of Construction: 316L SS | Gaskets/EPDM and Silicon | ||||||||||

| Air line | Line comes equipped with Rota meter, SIP inlet filter, and sparger. options include:

Ø Thermal mass flow controller Ø Dual inlet air filters (in series) Ø Oxygen supplementation Ø Dual inlet air filters w/integrity – test ports Ø Overlay valve |

|||||||||||

| Exhaust line | Line designed for minimal backpressure, unregulated, and comes standard with heated exhaust filter and manual backpressure regulator. Option include:

Ø Automatic back pressure control Ø Dual exhaust filters ( in parallel) Ø Exhaust condenser Ø Dual exhaust filters w/ integrity-test ports |

|||||||||||

| Temperature control line | All systems come with automatic sterilization as the standard. The line is designed to achieve temperature rises of 1°C/minute. Option include:

Ø Glycol Heat Exchanger |

|||||||||||

| Sensors | pH/DO kit | Redundant probe kit | ||||||||||

| Retractable probe housing | Redox probe and transmitter | |||||||||||

| Additional Options | Ø 21 CFR 11 compliant digital chart record

Ø Nova septum sampling systems Ø Inputs for ancillary devices Ø User-definable fixed speed pumps Ø Variable speed pumps Ø Foam/level kit Ø Vessel volume via differential pressure Ø 316L SS addition vessels Ø 7- or 12- port septum Ø CIP interface / spray balls Ø Load cells Ø Marine and pitched-blade impellers Ø Validation packages Ø Scales for addition vessel |

|||||||||||

بدون دیدگاه